John DiTonno of Philadelphia has a background in overseeing transportation, storage, and operations involving numerous logistics providers and local customers. He has led initiatives in optimizing transportation routes and cultivating relationships with key vendors, resulting in significant cost reductions and improved delivery times. In the following article, John DiTonno delves into the pivotal role played by robotics in revolutionizing warehouse operations, from optimizing inventory management to enhancing order fulfillment processes, ultimately driving efficiency gains and cost reductions.

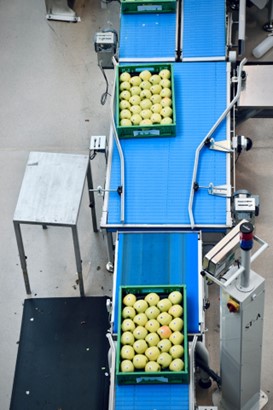

In logistics and supply chain management, the demand for efficiency and accuracy in operations has never been higher. As industries evolve and customer expectations continue to rise, warehouses are turning to innovative solutions to streamline processes and meet growing demands. Among these solutions, robotics and automation have emerged as game-changers, reshaping the landscape of modern warehousing and logistics.

John DiTonno of Philadelphia Discusses the How Robotics are Revolutionizing Logistics

John DiTonno says that traditionally, warehouses relied heavily on manual labor for tasks such as picking, packing, and sorting. However, with the advent of advanced robotics technology, warehouses are undergoing a transformation. Robotics systems, including autonomous mobile robots (AMRs), robotic arms, and automated guided vehicles (AGVs), are increasingly being integrated into warehouse workflows to perform repetitive tasks with speed, precision, and reliability.

Enhancing Efficiency in Inventory Management

Enhancing Efficiency in Inventory Management

One of the most transformative aspects of robotics in modern warehousing is its profound impact on inventory management. With advanced sensors and cutting-edge computer vision capabilities, robots can navigate through warehouse aisles with precision, scanning barcodes and conducting cycle counts with unmatched accuracy. This automation of inventory tracking and management processes ensures that warehouses maintain real-time visibility of stock levels, significantly reducing the occurrence of stockouts. Furthermore, robotics allows for the optimization of warehouse layout, leading to enhanced space utilization and ultimately greater operational efficiency. John DiTonno’s insights shed light on how these technological advancements are revolutionizing the way warehouses handle their inventory, paving the way for more streamlined and agile operations.

Streamlining Order Fulfillment Processes

In addition to inventory management, robotics plays a crucial role in streamlining order fulfillment processes. Cutting-edge robotic picking systems, leveraging the power of artificial intelligence and machine learning algorithms, are revolutionizing warehouse operations.

These robotic systems intelligently navigate the warehouse landscape, swiftly retrieving items from designated storage locations and meticulously assembling orders for shipment. John DiTonno underscores the significance of this automation in order processing, highlighting its ability to substantially diminish processing times while enhancing order accuracy.

Moreover, robotic picking systems empower warehouses to seamlessly handle increased order volumes, ensuring scalability and agility in meeting customer demands. As warehouses embrace robotics in their order fulfillment workflows, they unlock new avenues for operational optimization and customer satisfaction.

Driving Efficiency Gains and Cost Reductions

The integration of robotics and automation in warehouse operations offers numerous benefits beyond efficiency gains. John DiTonno says that by replacing manual labor with robotic systems, warehouses can achieve higher throughput rates, lower error rates, and reduced labor costs. Moreover, robotics enables warehouses to operate 24/7, maximizing productivity and throughput while minimizing downtime. Additionally, robotics technology allows warehouses to adapt quickly to changing demand patterns and scale operations accordingly, ensuring agility and responsiveness in today’s dynamic business environment.

Overcoming Challenges and Implementation Considerations

Overcoming Challenges and Implementation Considerations

Integrating robotics into warehouse operations offers undeniable advantages, but it also presents challenges that demand careful consideration. John DiTonno emphasizes the importance of thorough evaluation before adoption.

Warehouse managers must meticulously assess factors like initial investment costs, infrastructure adjustments, and compatibility with current systems to ensure seamless integration.

Additionally, preparing staff to collaborate effectively with robotic systems through comprehensive training programs is critical. Establishing robust maintenance protocols and reliable support channels is essential to sustain the long-term performance and functionality of robotic solutions. By addressing these challenges proactively, warehouses can maximize the benefits of robotics while minimizing potential disruptions to operations.

Conclusion

The integration of robotics and automation in warehouse operations, as highlighted by John DiTonno, represents a significant milestone in the evolution of logistics and supply chain management. As the demands for efficiency and accuracy continue to escalate in today’s dynamic business landscape, warehouses are increasingly turning to innovative solutions to streamline processes and enhance productivity. Robotics technology, including autonomous mobile robots, robotic arms, and automated guided vehicles, has emerged as a transformative force in modern warehousing, reshaping traditional workflows and driving operational efficiencies.

In conclusion, the integration of robotics and automation in warehouse operations represents a paradigm shift in the way warehouses handle inventory management and order fulfillment. By harnessing the power of robotics technology, warehouses can achieve higher levels of efficiency, accuracy, and scalability, ultimately driving cost reductions and enhancing customer satisfaction. As warehouses continue to embrace robotics, they are poised to unlock new opportunities for innovation and optimization in logistics and supply chain management.