Pneumatic valves may not grab headlines, but they quietly keep modern factories humming. Over the last few decades, companies that design and build these gadgets have piled up a surprising list of upgrades, certifications, and fresh ideas. Their work has become a main artery for the wider industrial-automation boom.

Faster machines, thriftier power use, and tighter device links-spare those buzzwords for your next staff meeting. They show exactly why valve tech-and the rules that circle it-had to level up. The roadmap ahead is simple. Pick a good automation-products distributor, lean on their stock, and let the paper chase go.

Date the idea to the 1800s if you really must, but the first production-grade valve did not show up until the 1900s. Those prototypes rarely talked back; operators nudged levers or cranked knobs to make things happen.

The first pneumatic valve makers built heavy, mechanical products for tough places such as mines and rail yards. Back then, workers shaped bronze and cast iron by hand, and every factory seemed to use its own sizing chart and pressure stamp. Standardization was a future guess at best.

After World War II, factories rushed to automate, and suddenly engineers wanted smaller valves that could stack, swap, and seal quickly. Port sizes, pressure limits, and core functions started lining up across brands so systems could play nice together instead of fighting each other.

A New Focus on Modularity and Smarter Tech

Lean production in the 1980s pushed valve builders to stop wiring everything as one big lump. Modular designs let technicians plug different types into the same manifold and call it done in half the usual time. Maintenance crews cheered.

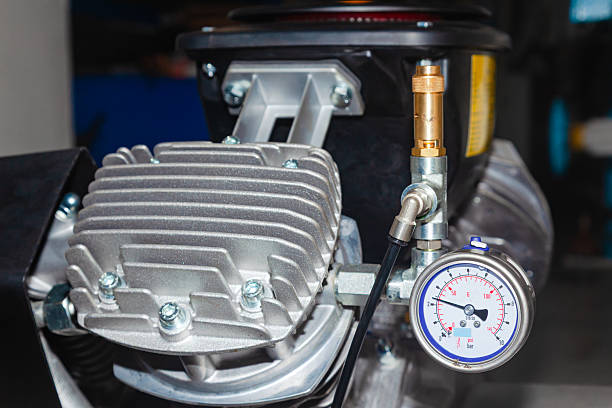

Now many valves carry their own brains. Sensors count puffs, spot leaks, and ping the control room before trouble shows up. Pharmaceutical lines, car assembly bays, and food-packaging floors swear these smart tricks keep their uptime golden.

The rapid spread of smart tech is shaking up the world of valve sales. Today, automation-products distributors juggle dozens of valve brands, a heap of technical specs, and quirky customer needs all at once.

Cross-border trade usually means crossing wires, and mismatched parts can slow anyone down. Common rules, like ISO 5599-1 for valve mounts and ISO 8573 for clean air, keep everyone speaking the same language.

Manufacturers that stick to these codes make their valves plug-and-play rather than trial-and-error. Buyers gain quicker setups, shorter headaches, and a supply chain that isn't constantly stumbling.

A shop that sources around the world should look for an automation-products distributor with stamped, compliant parts. Doing so helps customers hit the ground running today and stay on track tomorrow.

The world of pneumatic valves is changing quickly, and a few standout trends keep coming up.

Sustainability and Energy Efficiency

Compressed air ranks inch by inch as one of the priciest utilities you chew through on the factory floor. Fresh designs now lock internal leaks, speed up switches, and run on low-draw solenoids so that every puff counts. The payoff is fatter savings and a lighter touch on the electrical bill.

Customization and Industry-Specific Solutions

Off-the-shelf no longer rules the roost. Builders are rolling out corrosion-proof models for food lines, fire-safe valves for petro-chem zones, and even aluminum-wrapped options for high-static haunts. One part number rarely fits everybody anymore.

Integration with IoT and Digital Systems

Smart plant talk demands smarter chips. Many new valves now cradle sensors, log fieldbus chatter, and spit out performance data without breaking a sweat. That kind of linked hardware makes remote check-ups, instant re-mapping, and live number-crunching routine.

Regional Manufacturing Hubs and Supply Chain Flexibility

Trade winds and border rules keep shifting, so a growing number of brands are sewing up regional shops. Quick-response centers pop up from coast to coast, forcing distributors to juggle thinner pools of stock but deliver it faster. Lead times that once spooled out for weeks suddenly shrink to days.

Picking the right pneumatic valve distributor can feel like wandering through a maze. Use these simple checkpoints to find your way.

Stick this in your notebook: Companies that pair a trusted pneumatic valve supplier with a knowledgeable automation products distributor cut lead times, steady their quality, and keep systems humming smoothly from one factory to the next.

Pneumatic-valve makers have come a long way, and their story runs parallel to the boom in industrial automation. Once, workers cranked levers by hand; now, sensors talk to smart networks. That leap was possible only because engineers pushed the limits and because across-the-board standards let products play nice, no matter where they're made.

A solid automation-products distributor can keep a factory quick on its feet and ready for tomorrow's digitized floor. Whether you're retrofitting an old line or wiring up something brand-new, picking the right valves-and pairing them with an experienced partner-could be the move that decides your success.