That’s why selecting the right process — and aligning it with complementary capabilities like custom metal fabrication — isn’t just smart. It’s essential.

Take this example: a wearable tech startup invested $40,000 in tooling for a promising fitness tracker. Great design, solid market demand — but one critical oversight. They chose standard injection molding for a housing part that required ultra-fine detail. Weeks into production, the reject rate hit 38%. They had to scrap the mold and start over with micro-molding — costing them time, budget, and a first-mover advantage.

If your project involves both plastic and metal components, like brackets, housings, or internal supports, upstream coordination through a reliable custom metal fabrication partner can simplify fit and finish across materials.$40,000 in tooling for a promising fitness tracker. Great design, solid market demand — but one critical oversight. They chose standard injection molding for a housing part that required ultra-fine detail. Weeks into production, the reject rate hit 38%. They had to scrap the mold and start over with micro-molding — costing them time, budget, and a first-mover advantage.

Mistakes like this aren’t rare. They’re routine — and avoidable.

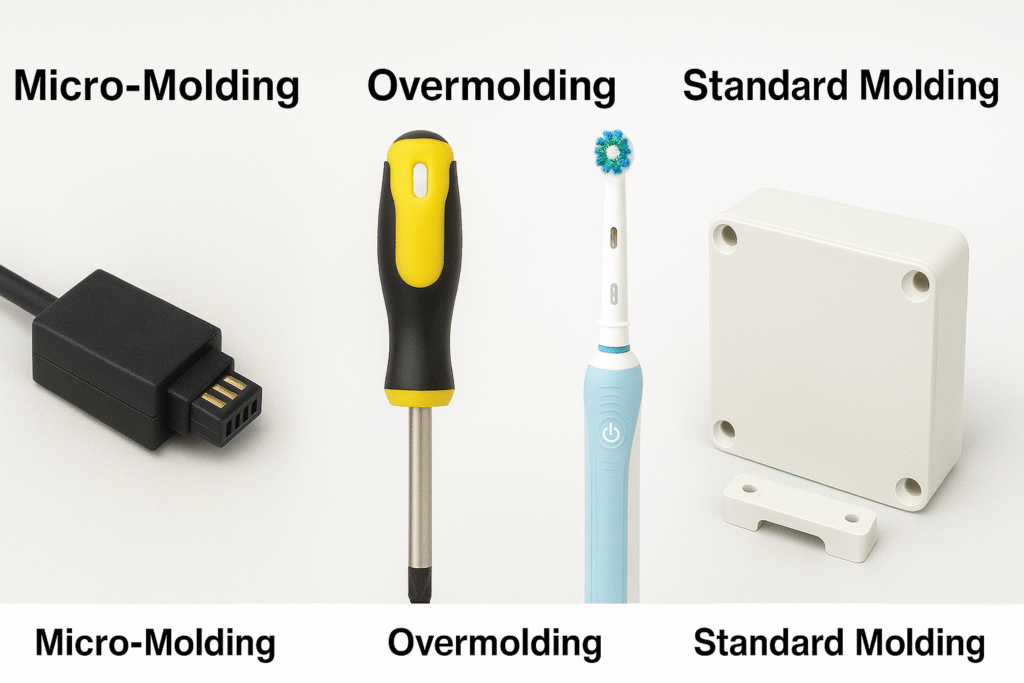

In 2025, engineering teams face more options than ever: standard injection molding, micro-molding, and overmolding — each with its own trade-offs in cost, precision, and speed. The smartest teams treat molding selection not as an afterthought, but as a core product strategy.

Let’s start with a quick decision framework — and help you avoid the mold trap before it starts. Before we dive in, it’s worth noting: if you’ve never worked with a professional plastic injection molding service, understanding what to expect — from tooling to tolerances — is just as important as picking the right method.

Before diving into specs and trade-offs, let’s frame your decision by evaluating three essential factors: part complexity, size/precision, and production volume.

Many design teams jump straight to quoting without re-evaluating whether the method they’re using truly fits the part’s lifecycle — from prototyping to full-scale production. But switching methods midstream often costs more than validating the right one upfront. Taking time at the decision stage protects against rework, tooling delays, and missed launch windows.

Does your part need multiple materials, soft-touch surfaces, or seals?

Tip: Don’t over-engineer. Overmolding adds tooling complexity and demands material compatibility.

Is your part extremely small, detailed, or fragile?

Warning: Micro-molding is a niche solution, not a prestige upgrade.

Are you producing tens of thousands — or just hundreds?

Standard injection molding is the most common method — and with good reason.

Example: Combining injection molding with custom metal fabrication for sensor housings can reduce vendor complexity and ensure better fit.

Micro-molding isn’t just smaller molding — it’s a different level of manufacturing. Think medical microfluidics, sensors, and devices under 1g.

Overmolding allows multi-material parts in one cycle — no gluing, welding, or separate assembly.

One common mistake is assuming overmolding is purely cosmetic. In reality, it often serves structural or safety-critical roles. For example, in medical tools and handheld devices, overmolding can improve grip in high-stakes environments — where slippage could cause damage or injury.

| Feature | Standard | Overmolding | Micro-Molding |

|---|---|---|---|

| Part Complexity | Low–Medium | Medium–High | High |

| Materials Supported | 1 | 2+ | 1 |

| Precision Capability | Moderate | Moderate | Very High |

| Tooling Cost | Low | Medium | High |

| Ideal For | Enclosures, caps | Grips, buttons | Sensors, micro-parts |

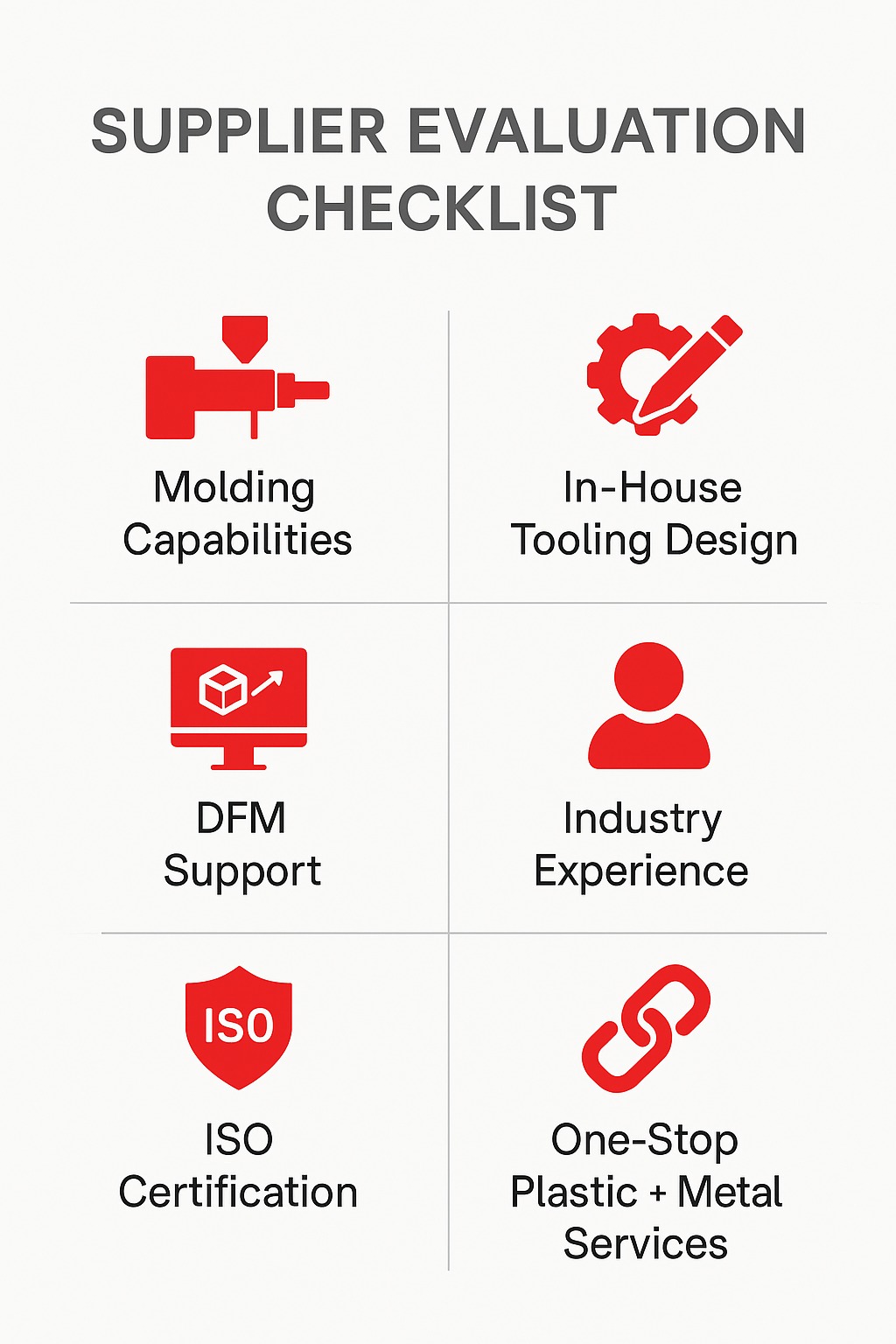

Even the best plan fails with the wrong execution. Your partner must:

Be cautious of suppliers that offer every molding method on paper but outsource key steps like tool design or part validation. Full integration — from tooling to QA to packaging — is what ensures accountability and faster iteration. Don’t just ask “can you mold it?” — ask “can you own the outcome?”

For example, a well-rounded plastic injection molding service provider should help you optimize design, tooling, and process parameters — not just quote a unit price. but outsource key steps like tool design or part validation. Full integration — from tooling to QA to packaging — is what ensures accountability and faster iteration. Don’t just ask “can you mold it?” — ask “can you own the outcome?”

Use this checklist before you commit:

Partners like CSMFG offer plastic injection molding services with in-house custom metal fabrication, helping OEMs reduce friction and risk.

Injection molding is not just a manufacturing step — it’s a strategic choice.

Choose the wrong method, and you risk rework, lost time, and failed parts.

Choose the wrong partner, and you’ll pay for it twice.

Choose wisely. Mold with confidence.