Investing in a co2 laser machine can be a smart move for businesses and hobbyists seeking to cut or engrave materials such as wood, acrylic, leather, and more with precision. However, before making a purchase, it’s essential to understand what distinguishes these machines, which features truly matter, and how to select the right one for your specific needs. From power ratings and material compatibility to software support and maintenance requirements, there’s a lot to consider. In this guide, we’ll cover everything you need to know before purchasing a CO2 laser machine, enabling you to make a confident and informed decision.

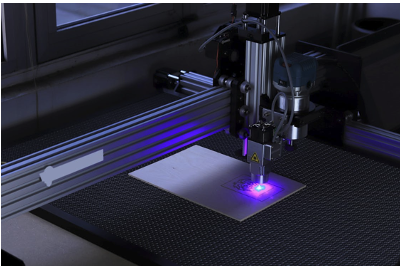

One of the first things you need to know before buying a CO2 laser machine is the type and power of the laser it uses. CO2 lasers typically come in different wattages, and the power level directly affects the machine’s ability to cut or engrave various materials.

Lower-wattage machines are ideal for light engraving and thin materials, while higher-wattage models are better suited for thicker cuts and faster processing. Understanding the type and power that best match your intended use will help ensure you get the performance you need without overpaying for unnecessary capability.

Another important factor to consider before purchasing a CO2 laser machine is its supported material range. While CO2 lasers are versatile and effective for non-metal materials like wood, acrylic, leather, paper, and certain plastics, not all machines handle every material equally well.

Some models may perform better with specific thicknesses or types, so it’s essential to match the machine’s capabilities with the materials you plan to work with. Checking the supported material range in advance helps you avoid limitations and ensures the machine meets your project or business requirements.

Cutting and engraving precision is a critical factor to understand before purchasing a CO2 laser machine. The level of accuracy a machine offers determines how clean and detailed your final results will be, especially for intricate patterns or fine engraving work.

Precision depends on factors like laser beam stability, motion control systems, and the quality of the machine’s optics. Choosing a machine known for high precision ensures professional-looking outcomes, reduces material waste, and minimizes the need for post-processing or touch-ups.

Machine size and workspace compatibility are key considerations when buying a CO2 laser machine. The physical dimensions of the machine should fit comfortably within your available workspace, providing sufficient room for operation, ventilation, and easy access for maintenance. Additionally, the cutting bed size should align with the typical material sizes you plan to use.

A machine that’s too small may limit your project scope, while one that’s too large can be impractical for smaller workshops. Evaluating both your workspace and project needs ensures you choose a machine that fits well and functions efficiently in your environment.

Software compatibility and ease of use are crucial factors to consider when purchasing a CO2 laser machine. The machine should work seamlessly with popular design software, such as CorelDRAW, AutoCAD, or Adobe Illustrator, allowing for smooth file transfers and an efficient workflow.

An intuitive user interface and clear controls make it easier to operate the machine, especially for beginners or teams with limited technical experience. Choosing a system with user-friendly software not only speeds up project setup but also minimizes errors and learning time, leading to better productivity and overall user satisfaction.

The type and efficiency of the cooling system are crucial to understand before purchasing a CO2 laser machine. These machines generate significant heat during operation, and without proper cooling, performance can drop, and components may get damaged. Most CO2 lasers use either air or water-cooling systems, with water-cooled models being more effective for higher-powered machines or extended use.

An efficient cooling system ensures stable operation, protects the laser tube, and extends the machine’s lifespan. Checking the type and quality of the cooling system helps you avoid overheating issues and ensures consistent, long-term performance.

Maintenance requirements and accessibility are crucial factors to consider before purchasing a CO2 laser machine. Regular upkeep is essential to keep the machine running efficiently, and understanding the necessary maintenance tasks—such as cleaning lenses, checking belts, or replacing parts—can help you plan accordingly.

A machine designed with accessible components makes these tasks quicker and easier, reducing downtime and the need for specialized technicians. Choosing a model with clear maintenance instructions and readily available parts ensures smoother operation and helps extend the machine's overall lifespan.

Brand reputation and customer support are key factors to consider before buying a CO2 laser machine. A well-regarded brand often reflects consistent quality, reliable performance, and customer satisfaction.

Equally important is the level of support provided—whether it’s help with installation, troubleshooting, or access to spare parts. Good customer support can save valuable time and minimize frustration, especially when unexpected issues arise. Researching reviews, user experiences, and the availability of local service centers can give you confidence in your purchase and ensure long-term peace of mind.

Price, warranty, and after-sales service are essential elements to consider before purchasing a CO2 laser machine. While it's tempting to focus on the lowest price, it’s important to balance cost with the value offered—such as included features, build quality, and support.

A solid warranty reflects the manufacturer’s confidence in their product and protects against early failures or defects. Additionally, dependable after-sales service ensures you have help when needed, from technical guidance to replacement parts. Taking all three into account helps you make a smarter investment that supports long-term reliability and satisfaction.

Buying a CO2 laser machine is a significant investment, and understanding the key factors before making a decision can save you time, money, and future frustration. From laser power and material compatibility to software integration, cooling systems, and maintenance needs, each element plays a role in how well the machine will serve your specific goals. Evaluating brand reputation, after-sales service, and warranty coverage adds another layer of confidence to your purchase.