A new jewelry brand launched with viral momentum—100K views on their teaser reel, dozens of pre-launch signups. But six weeks later, they were still waiting on samples. The factory went quiet, and their campaign collapsed before it began.

What went wrong? It wasn’t the design.

It was the process. Or rather, the lack of one.

Most founders hand over their sketch and hope it’ll be “taken care of.” But in real product development, hope is not a workflow—it’s a gamble.

From your first drawing to your customer’s unboxing moment, every phase introduces risk. What separates a growth-ready Jewelry Factory from a ghost supplier isn’t just price—it’s how they guide your product through that risk with structure, not guesswork.

This guide breaks down the process top brands use to go from sketch to shelf—and the questions you need to ask if you want to avoid losing your timeline, your margin, or your customer trust.

A beautiful sketch is worthless if the factory can’t turn it into something that works. You’re not just hiring a supplier to “make what you send.” You’re hiring a production translator—someone who takes design language and turns it into manufacturable geometry.

If you’re looking for a proven jewelry manufacturer that supports modern brands with real structure, flexible MOQs, and full design-to-delivery support, click here to learn more.

If your factory says “yes” to everything before asking a single question—run.

That’s not communication. That’s indifference wrapped in convenience.

Evyny supports the CAD design process by accepting a variety of inputs—including sketches or reference visuals—and helps convert them into build-ready 2D and 3D files, ensuring better alignment between creative intent and manufacturability. Before casting, you’ll see samples—wax or metal—that give you a real-world sense of proportion, detail, and feasibility.

This isn’t just professionalism—it’s preventative engineering.

Sampling isn’t optional. It’s the last chance to catch what a drawing can’t show. And when factories skip or rush this stage, you pay for it later—in refunds, remakes, and lost trust.

“Looks okay” isn’t a pass. “Feels right, wears right, photographs well” is.

Evyny incorporates sampling into its OEM/ODM workflow, allowing brands to preview pieces with proposed finishes and make refinements before final production. This reduces misalignment and supports better first-run outcomes.

A good sample doesn’t just preview the product. It validates the entire system behind it.

Anyone can make one nice unit. Real factories prove their value when you order 300 pieces and the 299th looks exactly like the 3rd.

This is where most low-cost manufacturers fail. They have no quality rhythm—just reaction.

Ask: Who signs off your QC checkpoints? If the answer is vague or passive, assume none.

Evyny builds quality control into every phase. From metal casting to polishing, every production batch is reviewed before proceeding. Their plating process meets 2.5-micron standards, and polishing includes multiple tool-based and manual inspections—ensuring durability and shine that meet international expectations.

You could make the most beautiful jewelry in the world. But if it arrives scratched, bent, or rattling around in a plastic pouch, you’ve just lost the customer’s trust.

Packaging isn’t just protection—it’s perception. And for digital-native brands, it’s the most overlooked source of conversion loss.

Packaging isn’t a cost center. It’s a conversion asset.

Evyny provides packaging support as part of their production process. Brands can provide their own materials or consult Evyny for sourcing assistance. Packaging focuses on both presentation and protection, aiming to meet the standards of modern jewelry fulfillment.

This phase may be last in the line—but it’s the first in your customer’s memory.

It doesn’t matter how skilled your factory is—if you don’t know what’s happening, you’re guessing on launch dates, wasting influencer windows, and scrambling fulfillment.

A manufacturer who doesn’t report problems early isn’t confident—they’re reactive.

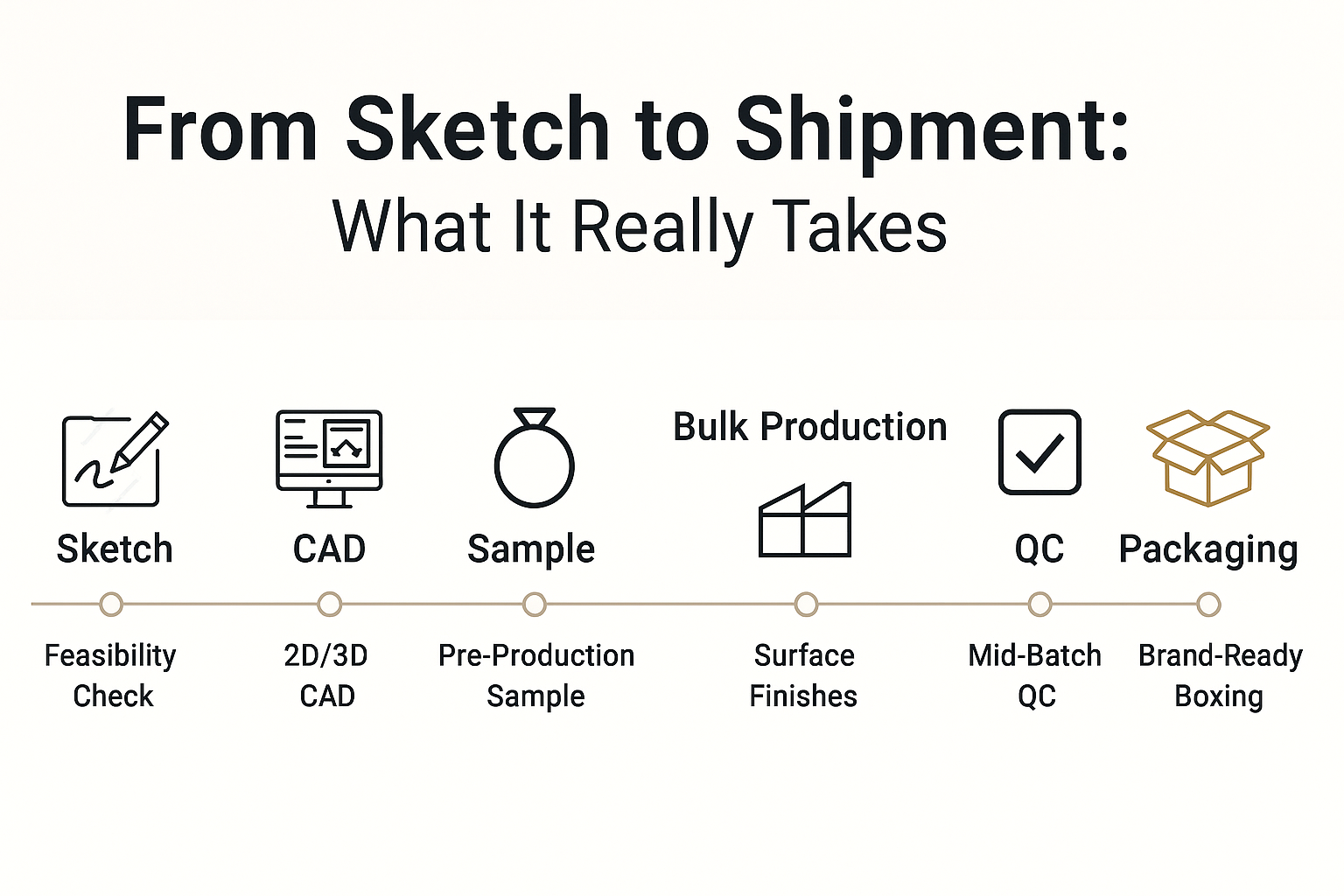

Evyny’s workflow maps to 6 clear phases (CAD → Mold → Sample → Confirm → Produce → Pack), and each one comes with shared checkpoints. Founders don’t have to chase updates—they’re built into the system.

This kind of communication doesn’t just make you feel informed—it helps you build launch calendars with confidence.

Most factories are designed for one order. Great factories are designed for momentum.

If you’re serious about scaling, ask:

A factory that plans ahead with you reduces chaos, lowers your cost, and gives your ops team room to breathe.

Evyny helps maintain consistency in follow-up production by referencing previous design and plating specifications—supporting smoother reorders without unnecessary rework. QC protocols are documented. Repeat orders stay consistent. If you’re building SKUs in public—drop by drop—this level of systematization is critical.

If you’re picking a Jewelry Factory based on price alone, you’re betting your launch on chance.

Smart brands pick a partner who owns the process.

Here’s what that looks like:

If your current factory can’t answer how they handle each of these—it’s not a factory. It’s a quote machine.

You’re not just building jewelry. You’re building a system of trust—between you, your factory, and your customer.

And systems don’t run on hope. They run on process.