Forklifts are often described as workhorses, but even the toughest machines wear down faster when the parts supporting them are not up to standard. Many breakdowns occur due to age and heavy usage, with all issues ultimately tracing back to one major factor, which is the quality of each part.

The materials, tolerances, and manufacturing standards behind each component shape how long a forklift remains reliable, safe, and cost-effective.

Hence, this article will elaborate more on how each part contributes to its efficiency and quality determines its lifespan in the long run.

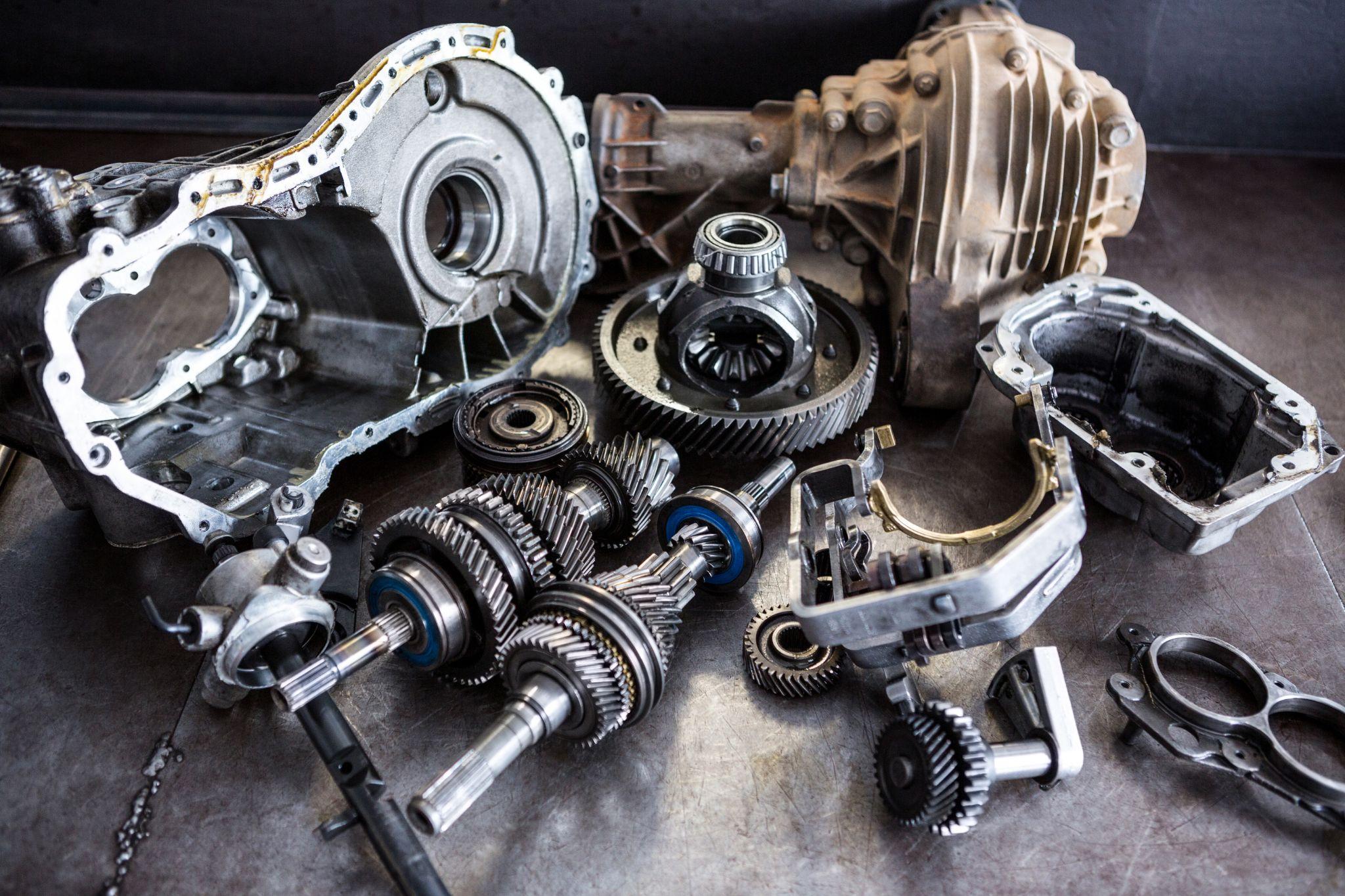

Wear parts, such as rollers, chains, seals, and bushings, are designed to degrade gradually. However, when these parts are made with inferior materials, they deteriorate rapidly, bringing adjacent components down with them.

A low-quality seal, for example, may leak prematurely, contaminating hydraulic systems and reducing the lifespan of pumps and cylinders that would otherwise last much longer.

Likewise, every forklift operates under constant mechanical stress, where lifting, braking, turning, and lowering loads all transfer force through dozens of interconnected parts.

High-quality components are designed to absorb and distribute that stress evenly, while lower-quality parts tend to concentrate it in weak points. Over time, uneven stress accelerates fatigue, leading to cracks, deformation, and premature failure across the system.

Precision also matters more than it appears because quality forklift parts are manufactured to tight tolerances, ensuring proper alignment and smooth interaction with surrounding components.

When tolerances are loose, parts rub, bind, or vibrate excessively. This friction increases heat, accelerates wear, and slowly erodes performance; thereby causing the forklift to feel less responsive, even if no single part has completely failed yet.

Below are more details on how some of these parts affect efficiency:

Hydraulic systems are especially sensitive to the quality of their parts, as pumps, hoses, valves, and cylinders rely on clean seals and consistent pressure.

Inferior hydraulic parts often degrade internally, shedding particles that contaminate fluid. Once contamination begins, it circulates throughout the system, damaging components that may still be structurally sound.

This is why professionals like Sidekick Attachments often emphasize the importance of proper maintenance after long-term usage. Once they become faulty, replacement is always the best option, meaning high-quality hydraulic parts protect not only themselves but also the entire hydraulic network.

Considering the structural integrity of this part, high-quality forks are forged and heat-treated to resist bending and cracking under repeated stress.

Although lower-quality forks may appear adequate at first, they gradually deform, altering the load balance and increasing the strain on the mast, carriage, and frame, thereby shortening the forklift's lifespan as a whole.

Modern forklifts rely heavily on electrical components, including sensors, wiring harnesses, and control modules. Quality electrical parts, however, resist moisture, vibration, and temperature fluctuations.

Poor-quality alternatives degrade insulation, corrode internally, or lose signal consistency, causing electrical instability that leads to intermittent faults, which are difficult to diagnose and often misattributed to other systems, prolonging downtime and accelerating overall wear.

In addition, high-quality parts extend maintenance intervals by wearing predictably, which allows technicians to plan replacements based on known service life rather than reacting to unexpected breakdowns.

Poor-quality parts create erratic maintenance cycles, where issues appear earlier and more frequently. This reactive maintenance accelerates wear across the forklift, as components are repeatedly disassembled and reinstalled.

Small rotating components such as bearings and rollers influence how smoothly a forklift operates. When these parts are well-made, movement remains controlled and quiet.

However, when quality is lacking, they introduce vibration that travels through the mast and frame. Over time, this vibration loosens fasteners, stresses welds, and weakens structural components that were never designed to absorb constant oscillation.

Although it is important to know that brakes, limit switches, load sensors, and safety interlocks are only as reliable as the parts inside them. High-quality safety components maintain a consistent response over years of use, and inferior parts drift out of calibration or fail without warning.

When safety systems degrade, operators compensate subconsciously, placing additional strain on the machine and increasing the risk of sudden catastrophic failure.

Forklifts are engineered as integrated systems, which is why high-quality parts are designed to match original specifications, ensuring compatibility across components.

However, poorly matched parts create misalignment, uneven load distribution, and inconsistent performance. Even if the part itself survives, it often causes accelerated wear elsewhere, effectively trading one short-term fix for long-term damage.

Over time, they also increase the total cost of ownership through frequent replacements, secondary damage, and downtime.

Forklift lifespan is not determined solely by age, but by the quality of the parts that carry daily stress. Every component, from the smallest bearing to the largest hydraulic cylinder, plays a role in how evenly wear is distributed across the machine.

Therefore, investing in high-quality forklift parts is ultimately an investment in stability, safety, and longevity, ensuring the equipment remains productive long after shortcuts would have taken it out of service.