Modern Manufacturing is driven by speed and precision in order to get outputs of impeccable quality. With the surge of complicated designs, the rise of advanced manufacturing such as CNC grinding services is becoming increasingly popular. Tight tolerances in both time and accuracy from industries are further fuelling the shift. China’s CNC machining services has one of the most advanced technologies competitively priced which makes it very reliable for outsourcing these services.

In this article, we take a closer look at the main benefits of CNC grinding services in modern manufacturing and why it is so popular among B2B companies.

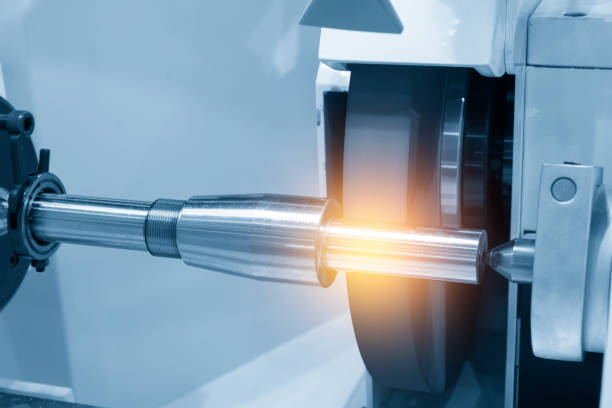

CNC grinding is the process of removing material from a workpiece, with the help of a computer-controlled rotating wheel. It is a highly adaptable process that can be used to shape and finish metals, plastics, and ceramic materials. For example, CNC surface grinding and tool grinding can be performed with the oxidizing wheel or with precision dying. CNC grinding services offer extreme precision and apply to all types of devices including electronics, medical devices, and automotive parts.

As it is done with a computer, CNC grinding is favored by most manufacturers because of the flexibility and customization it offers. Components are produced with the exact measurements and surface finishes enabling them to withstand extreme heat and pressure which is critical for performance-durable parts. Because of this exceptional level of adaptability, CNC grinding has become an essential piece of machinery to high-performance staffing industries.

China CNC machining services have gained popularity in precision engineering due to the incredible accuracy they provide. Unlike manual bone-cutting, where the craftsman relies on his skills, CNC bone cutting uses the computer numerical control system, which enables intricate designs to be loaded on the server and the machine does the rest. This greatly minimizes human error and provides repeatability in output across several cycles. The advanced CNC machines bolster the accuracy and repeatability in bone contours to within one hundred microns. That is a level of precision not possible or extremely difficult to achieve manually. Precision engineering fields including aerospace, medical devices, and automotive have exacting standards that must be adhered to, and the unrivaled ability to meet required tolerances for bone transitions CNC bone cutting into an invaluable technology. Moreover, CNC machines automatically precision grind the parts, making them of specific standards with the desired quality. The advanced level of control over engineering parameters enables accurate replication of components with distinctly minimal differences. This guarantees that every item manufactured will comply with the precise requirements for competing in the modern demanding sectors. Being able to provide such accuracy in bulk can be helpful in competing against rivals in the industry.

CNC grinding services come with immense advantages, speed being one of them. Renowned for pulling off quick production timelines, the CNC Machining Services China is willing and able. With CNC machines, processes are further automated and sped up in comparison to manually operated methods. With speed comes a reduction in lead time, allowing businesses to comfortably meet strict deadlines while maintaining top tier quality.

CNC grinding machines are highly effective for high output production since they are capable of working non-stop with only a little downtime in between. While a human operator needs to constantly stop to change settings and look at work pieces, a CNC machine can automatically and continuously grind with utmost precision. High levels of automation improves efficiency, especially for manufacturers who have urgent high quantity demands. Moreover, as CNC machines simultaneously work on various parts, the production time improves drastically, leading to better fuels and turnaround times. Being able to produce a high volume of products in a short span of time, businesses are able to stay ahead of their competition with a product that doesn’t compromise on quality.

One more benefit to CNC grinding services is the ability to do a multitude of tasks. These services are useful in a wide variety of processes, ranging from shaping parts to finishing details. It does not matter if a component needs a sleek, polished look or if a hardened material needs to be cut into; CNC grinding can achieve top tier results every time.

Machining services in China offer many different types of CNC grinding, including external, internal, and surface grinding. Each of these methods has specific uses and a particular way that it can be done. Flat, shaped surfaces require surface grinding while precise cylindrical shapes need to be created with cylindrical grinding. This permits a whole assortment of companies from the automotive and electronics industry to take advantage and get their particular production requirement to be met through CNC grinding. CNC grinding permits parts to be produced with an assortment of shapes and sizes beyond the manual techniques, especially with high level accuracy and precision surpassing other machines. It creates efficiency when dealing with intricate parts that would otherwise waste time needing several stages to complete.

The modern manufacturing process would not be the same without CNC grinding services. B2B companies in every industry, especially those that require high-end components, stand to reap the benefits of these services due to improvements in efficiency, precision, savings, and flexibility.

CNC Machining Services China offers faux pas solutions as a first step in modular integrated manufacturing processes,one-stop workshop system from casting, cnc precision machining, surface treatments, to assembly deliver high standard quality for global aerospace systems and automotive industry requirements. In the continual grappling advancement of global manufacturing, things have to be done in more efficacious ways, CNC grinding will primarily aid in the meeting out of the need for precision and reliability in the output of goods.

The CNC grinding services can aid in the improvement of the business processes, greatly cut down the expenses, and contribute to building of credible products. Getting ahead of the competition and giving them what they expect in precision-engineered fittings can be delivered through advanced CNC grinding services. For CNC grinding service, the right supplier has to be picked, this can largely be done through CNC Machining Services China, for better quality, economical, and innovative objectives.